Bob nick wrote:

說到避震

很像原廠又很像KYB,你們有誰看過嗎?

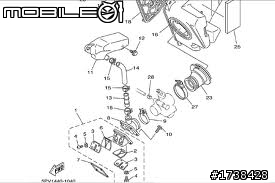

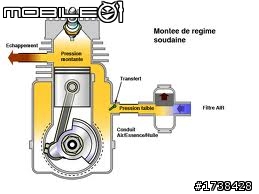

這應該是KYB+YEIS哈哈哈哈哈 我是來亂的 不過有個好圖給大家看看

所以大家來搞這個吧 原來還有這種好東西 哈哈

※ 引述《finest (RG125~~)》之銘言:

: 大多2T在改的

: 主要是提昇低轉速扭力

: 那4T改裝的效果應該有限?

YEIS 看到 Y 也知道是 YAMAHA 的產物......

全名是 YAMAHA ENERGY INDUCTION SYSTEM"源誘導系統

"目的在於解決引擎在某轉速時無法避免之扭力降的情況,

一般在二行程上適用 [1983年發表]容我再次叨擾一下...

因為 REED VALVE [簧片閥]發明,造福了許多的騎士,

但是許多副作用可能大家沒有仔細發現,

即是排氣壓力波的影響,造成曲軸箱內的真空度不足,

氣體想從REED-VALVE衝進曲軸箱,內做充氣之動作,

卻不得其門而入,停在REED-VALVE另一側,

當下次一有機會連本帶利的灌進去....

造成太濃現象,這種情形在低開度低轉速最明顯,

因為每個工程師只能對對一點做最大馬力調諧

[例如:6500RPM最大馬力,4500即發生扭力降]這現象

嚴重嗎,對速克達還好,但打擋車可能會遇到....

如何解決....何姆何姿 理論......

求出最佳的 容積 長度 管徑 [找到4500之共振波]

原理很簡單:

同上述沒法通過簧閥片的油氣,

向上進入到YEIS之容積[負壓處],下一回隨油氣[己充淡]

一齊灌下去到曲軸箱內進氣....YEIS 不能改善性能,

但可以恢復低速力道,您覺得追風是不是低速比

王牌順[其實最早國內DT 就有了],

NSR的確有個小香菇在那,雖不叫YEIS 也是同樣理,

看起來轉速設定高很多,可能與空間也有關係....

基本上yeis的動作跟高轉速及低轉速沒有太大的關係,

而是舌簧伐的開閉動作不過卻是影響低轉速的扭力輸出是沒錯,

yeis正是〝壓力變動吸收室〞,因為引擎在吸氣時舌簧片是一開一閉,

因此在舌簧閥關閉時,岐管內的壓力會增加,

這是吸氣慣性,所以如果岐管內的空間越大,

可以緩衝回壓的力道,因此油氣不易因回壓而發生逆流,

我是指往化油氣外倒流,而越大的空間增加同体績的氣体

會比小空間壓力變化小,如果沒有逆流發生,那下次的進氣動作就會更順暢,

但又因岐管的長度會影響引擎轉速的上限,岐管越短轉速可越高,

所以在又要岐管短又要空間大且又不能破壞岐管內的流体效率下,

開一孔外接"壓力變動吸收室"的YEIS就被設計出來了,這樣說清不清楚?

另外yamaha的設計不單單如此,

因為yeis的設計是用來增加低轉速的扭力輸出,

一般2t車都偏向高轉速,在轉速為達引擎的最大出歷時往往會軟弱無力,

等轉速一到爆發力則一下爆出,呈如honda自豪的rc閥一樣,

yahama也有針對高轉速而設計的ypvs,

所以正常在一台yamaha的2t車子上應該會有這2項裝置,

yeis早在1980年代初期就已經裝置在rz的車系了,

總知講這麼多還不如自己看一次,看過就知道了!

--

以上轉錄......

--

思念 是從回憶深處伴著微風而來的熟悉香味

http://home.kimo.com.tw/cyf24018/

基維百科:

二衝程動力閥系統

從維基百科,自由的百科全書

二衝程的功率閥系統是改善傳統的兩衝程發動機,使在更廣泛的的高功率輸出的轉速範圍。

目錄 [ 隱藏 ]

1 操作的二衝程發動機

2 工程設計的改進

2.1 鈴木AETC和超級AETC

2.2 YPVS雅馬哈動力閥系統

2.3 本田ATAC

2.4 本田電源端口閥

2.5 本田V - TACS

2.6 本田RC閥

2.7 川崎KIPS

[ 編輯 ] 二衝程發動機的運作

中風是一個行動,其全長缸活塞行駛。在二衝程發動機,兩招之一,結合進氣衝程和壓縮衝程,而其他中風結合燃燒衝程和排氣衝程 。

由於活塞在汽缸向上中,它創建在低壓區曲軸箱;吸取新鮮的空氣和通過了一個洞,從化油器 霧化燃油在汽缸壁或直接進入曲軸箱。當活塞繼續向上行駛,傳輸端口和排氣口被封閉,從而滯留在燃燒室的可燃混合氣。當活塞到達缸的頂部,氣缸的混合氣被壓縮到著火點 。

開始一次點火發生第二次中風。動力衝程開始後的空氣燃料混合物被點燃。燒毀燃料創建在上述活塞缸的壓力,迫使它下降 。當活塞通過中點的衝程,汽缸側面的排氣口是發現並開始燃燒的燃料流入膨脹室或消聲器通過多方面的。

當活塞向下移動,空氣燃料混合物仍然從以前的攝入量壓縮衝程。排氣口後不久,活塞向下行程中發現,轉讓港口開始被發現。作為一個通道,通過它的空氣燃料混合物從曲軸箱進入上述活塞缸的傳輸端口。一旦活塞到達中風的底部,第二個週期完成,並重複這個過程。

[ 編輯 ] 工程設計的改進

簡單的兩衝程發動機內唯一的運動部件的曲軸,連桿,活塞。這是相同的設計簡單,但是,這使得兩衝程發動機省油。在動力衝程的底部,開放的傳輸端口,提供了新鮮的燃料,同時在排氣口。這使得相當數量的新燃料通過發動機運行直沒有被用於電力生產。正確設計的排氣系統,有助於最大限度地減少原燃料在排氣過程中損失量,但兩衝程發動機總是會浪費一些燃料。

許多生產者的二衝程性能自行車配合排氣閥系統。這些閥門的行為,不同的高度和寬度從而擴大權力在更寬的轉速範圍內提供的排氣端口 。固定尺寸的排氣口只產生在一個狹窄的轉速範圍內,這也影響到油耗和排放的可用功率。

在自行車比賽中,這是沒有問題的發動機將在高轉速運行幾乎所有的時間。然而,在道路/通勤自行車,在有限的權力範圍內的問題。為了提供更多的低轉速功率,以及使發動機產生大量的高轉速功率,動力閥系統使用。

所有的動力閥系統不同的排氣口開放時間,使發動機可用的低端電源,具有優良的高端功率時間。製造商還包括子排氣腔,延長“調整長度的膨脹室。

電力閥門驅動可通過機械(RPM的依賴)或電動(伺服電機)意味著越來越多的電子控制。電子控制提供了更大程度的準確性,以及能夠改變閥門的開度,並進行調整的條件。

[ 編輯 ] 鈴木AETC和超級AETC

AETC和超級AETC鈴木的發動機,自動排氣定時控制:兩個刀片版本安裝VJ21 RGV250,三葉片版本,VJ22 RGV250 和鈴木 RG150 。

AETC系統,電源閥系統通常是局部封閉在低轉速;關閉時,它使發動機,以使更多的權力。截至到某一點,但是,功率下降,發動機足夠的氣體無法排出的廢氣。當閥打開電源,它可以讓更多的氣體流量的排氣口。這個系統是由排氣口上方的一個小方塊辨認;電源閥門坐落在此框中。根據閥門,它們可能是由兩個(舊版本)或三個(更新版本)單獨的刀片。

[ 編輯 ] YPVS雅馬哈動力閥系統

YPVS雅馬哈發動機,雅馬哈動力閥系統:雅馬哈工程師意識到,通過改變排氣口的高度,他們可以有效地改變發動機的動力傳遞,從而整個轉速範圍內最佳的功率和扭矩,所以 ,YPVS出生。閥橫穿排氣口上方的圓柱形設計,它是由伺服電機控制從控制CDI(和其他地方)的信息框打開 。該閥是稍微ovular的形狀 。這將改變排氣口的高度和大小不同的發動機轉速,最大限度地在所有轉速範圍內的可用功率。它是適合所有的RZ / RD二衝程公路自行車後面模型(125,250 350和500毫升),TZR範圍,以及大部分的YZ系列摩托車越野自行車。YPVS是唯一液冷自行車不風冷版本。雅馬哈也用在以後TZR250R SPR模型等模型斷頭台的版本 。雅馬哈DT125R是一條街法律的125CC ENDURO摩托車 。

雅馬哈是實際上的第一家公司,生產與他們的種族自行車YPVS一致的結果 。1977年OW35K是第一場比賽的自行車納入動力閥系統,它在1977年獲得芬蘭大獎賽。Kadenacy效果是利用和控制點,給雅馬哈很大的優勢超過所有其他製造商在整個70年代後期到80年代中期。YPVS第一街自行車RZ/RD350 YPVS(LC2起),並RZ/RD500 GP副本在1983-84。一

[ 編輯 ] 本田ATAC

ATAC系統:本田自動扭矩放大室系統,有效地增加或減少之前位於排氣連接一個小的蝴蝶閥的排氣系統的體積。在低轉速離心式曲軸驅動齒輪,閥門打開成一個小室,增加排風量,使廢氣流通過商會。在高轉速的ATAC閥門關閉和膨脹室的排氣,只需將退出。一個較大的膨脹室,允許更多的權力,因為在低轉速的衝動“反彈”增壓效果所需的額外時間。它被用來對他們華潤 motocrossers,GP自行車和MVX,NS和NSR的公路自行車。

[ 編輯 ] 本田電源端口閥

HPP的閥門。一個離心調速打開和關閉兩個刀片排氣閥(超過 50份)

[ 編輯 ] 本田V - TACS

的“V - TACS” - 可變扭矩放大室系統 - 從“AETC系統”的工作方式不同,它只會工作在同一個調諧的消聲器一起使用時,。調諧的消聲器/擴展商會增加,但只有在他們設計的轉速功率,實際上可以導致功率損耗外的調整轉速。“V TACS系統”的使用,而不會失去權力膨脹室的調整轉速外的膨脹室的優勢。的頭部和發動機汽缸內,有一個閥門的密封腔。這種密封腔發洩到排氣口的閥門打開時。在低轉速閥門打開,這增加排氣管的體積和否定功率損耗,通常會在低轉速,膨脹室明顯的效果。在中轉速閥門關閉,這使得膨脹室的工作。這是確定由蓋和氣缸,比正常位移較大,筒壁也投與它的措辭 VTACS。

V - TACS是一個腳踏式電源閥系統由本田一樣,本田FC50一些小兩衝程摩托車和踏板車。

[ 編輯 ] 本田RC閥

本田革命控制閥的設計和工作原理像“AETC系統。” 一台小型電腦監控發動機轉速和調節兩片排氣閥與電動伺服。本田配備很多,如二衝程摩托車RC和NSR125與NSR250模型-閥門電廠。

[ 編輯 ] 川崎KIPS

川崎使用閥的電源系統,稱為二衝程自行車 KIPS(川崎集成Powervalve系統)。KIPS利用港口的高度都改建,關閉二級管道端口,和一個諧振腔。KIPS是由機械省長。

原文版:

From Wikipedia, the free encyclopedia

The two-stroke power valve system is an improvement to a conventional two-stroke engine that gives a high power output over a wider RPM range.

Contents [hide]

1 Operation of a two-stroke engine

2 Engineering design improvements

2.1 Suzuki AETC and Super AETC

2.2 YPVS-Yamaha Power Valve System

2.3 Honda ATAC

2.4 Honda Power Port valve

2.5 Honda V-TACS

2.6 Honda RC-Valve

2.7 Kawasaki KIPS

[edit]Operation of a two-stroke engine

A stroke is the action of a piston travelling the full length of its cylinder. In a two-stroke engine, one of the two strokes combines the intake stroke and the compression stroke, while the other stroke combines the combustion stroke and the exhaust stroke.

As the piston travels upward in the cylinder, it creates low pressure area in the crankcase; this draws fresh air and atomized fuel from the carburetor through a hole in the cylinder wall or directly into the crankcase. As the piston continues travelling upward, transfer ports and the exhaust ports are closed off, thus trapping the combustible mixture in the combustion chamber. As the piston reaches the top of the cylinder, the mixture in the cylinder is compressed to the point of ignition.

The second stroke begins once ignition has taken place. The power stroke begins after the air-fuel mixture is ignited. The burnt fuel creates pressure in the cylinder above the piston and forces it downward. As the piston passes the midpoint of the downstroke, the exhaust port to the side of the cylinder is uncovered and initiates the flow of burned fuel out into the expansion chamber or muffler through the manifold.

As the piston moves downward,where the air-fuel mixture remains from the previous intake-compression stroke. Shortly after the exhaust port is uncovered by the downward travel of the piston, the transfer ports begin to be uncovered. The transfer ports act as a passage through which the air-fuel mixture moves from the crankcase into the cylinder above the piston. Once the piston reaches the bottom of the stroke, the second cycle is completed and the process is repeated.

[edit]Engineering design improvements

The only moving parts inside simple two-stroke engines are the crankshaft, the connecting rod, and the piston. It is the same simplicity in design, however, that makes a two-stroke engine less fuel-efficient. At the bottom of the power stroke, the transfer ports, which deliver fresh fuel, are open at the same time as the exhaust port. This allows a significant amount of fresh fuel to run straight through the engine without ever being available for power production. Properly designed exhaust systems help minimize the amount of raw fuel loss in the exhaust process, but a two-stroke engine will always waste some fuel.

Many producers of two-stroke performance bikes fit them with the exhaust valve systems. These valves act to vary the height (and width) of the exhaust port thereby broadening power delivery over a wider rev range. Exhaust ports with fixed dimensions only produce usable power in a narrow rev range, which also affects fuel consumption and emissions.

In a race bike, this is not a problem as the engine will be operating at high RPM almost all the time. However, in a road/commuter bike, the limited power range is problem. To provide more low RPM power, as well as enable the engine to produce a lot of high RPM power, a power valve system is used.

All power valve systems vary the duration of the exhaust port open time, which gives the engine usable low end power combined with excellent top end power. Manufacturers have also included sub exhaust chambers that extend the 'tuned length' of the expansion chamber.

Power valve actuation can be by mechanical (RPM dependent) or electric (servo motor) means increasingly with electronic control. Electronic control offers a greater degree of accuracy as well as being able to vary the opening of the valve and be tuned to conditions.

[edit]Suzuki AETC and Super AETC

AETC and Super AETC Suzuki engines, Automatic Exhaust Timing Control: The two-blade version was fitted to the VJ21 RGV250, and the three-blade version, to the VJ22 RGV250 and Suzuki RG150.

With the AETC system, the power-valve systems are normally partially closed at low RPM; when closed, it enables the engine to make more power. Up to a certain point, however, power drops off as the engine is unable to expel enough gases out of the exhaust. When the power-valve is opened, it allows more gases to flow out of the exhaust port. This system is recognizable by a small box above the exhaust outlet; the power-valves are situated in this box. Depending on the valve, they may be made of two (older version) or three (newer version) separate blades.

[edit]YPVS-Yamaha Power Valve System

YPVS Yamaha engines, Yamaha Power Valve System: Yamaha engineers realized that by altering the height of the exhaust port they could effectively change the engine power delivery thereby having optimal power and torque across the entire rev range, so it was that the YPVS was born. The valve is of a cylindrical design running across the top of the exhaust port, it is turned by a servo motor controlled from a control box taking information from the CDI (and other locations). The valve is a slightly ovular shape. This changes the height and size of the exhaust port at different engine speeds, maximizing the available power at all rev ranges. It was fitted to all of the later models of the RZ/RD two-stroke road bikes (125, 250 350 and 500 cc), the TZR range, as well as most of the YZ series of motocross bikes. The YPVS is only found on the liquid-cooled bikes not air cooled versions. Yamaha have also used a guillotine version in some of their later models such as the TZR250R SPR model. Yamaha DT125R is a street-legal 125cc ENDURO motorbike.

Yamaha was actually the first company to produce consistent results with their YPVS in their race bikes. The 1977 OW35K was the first race bike to incorporate the power valve system and it won the Finnish GP in 1977. The Kadenacy effect was harnessed and controlled to a point that gave Yamaha great advantage over all the other manufacturers throughout the late 70's and into the mid 80's. The first street bikes with YPVS were the RZ/RD350 YPVS (LC2-onwards), and RZ/RD500 GP Replica in 1983-84. A

[edit]Honda ATAC

ATAC System: The Honda Automatic Torque Amplification Chamber system works by effectively increasing or decreasing the volume of the exhaust system with a small butterfly valve located just before the exhaust connection. At low RPM a centrifugal crankshaft driven gear opens the valve into a small chamber and increases the volume of the exhaust by allowing the exhaust gases to flow through the chamber. At high RPM the ATAC valve is closed and the exhaust simply exits into the expansion chamber. A larger expansion chamber allows for more power at lower RPM's because of the extra time needed for the impulse to "bounce" back for the supercharger effect. It was used on their CR motocrossers, GP bikes and MVX, NS and NSR road bikes.

[edit]Honda Power Port valve

HPP valve. A centrifugal governor opens and closes a two-blade exhaust valve (using over 50 parts)

[edit]Honda V-TACS

The "V-TACS" - Variable Torque Amplification Chamber System - works differently from the "AETC system" and it will only work when it is used in conjunction with a tuned muffler. Tuned mufflers/expansion chambers increase power but only at the RPM they are designed for and can actually cause a power loss outside their tuned RPM. "V-TACS system" takes advantage of using an expansion chamber without losing power outside the expansion chamber's tuned RPM. Within the head and cylinder of the engine, there is a chamber that is sealed by a valve. This sealed chamber is vented onto the exhaust port when the valve is open. At low RPM this valve is open, this has the effect of increasing the exhaust manifold volume and negating the power loss that would normally be apparent at low RPM with an expansion chamber. At mid RPM the valve is closed, this enables the expansion chamber to work. It is identified by the head and cylinder, being much larger than normal for its displacement, the cylinder wall is also cast with the wording VTACS on it.

V-TACS was a foot-operated power valve system made by Honda on some of its small two-stroke bikes and scooters, like the Honda FC50.

[edit]Honda RC-Valve

The Honda Revolution Control valve is designed and works in principle like the "AETC system." A small computer monitors engine RPM and adjusts a two-blade exhaust valve with an electric servo. Honda equipped many two-stroke motorcycles such as the NSR125 and NSR250 models with RC - Valve power plants.

[edit]Kawasaki KIPS

Kawasaki uses a power-valve system called KIPS (Kawasaki Integrated Powervalve System) on their two-stroke bikes. The KIPS utilizes both alterations in port height, closing of the secondary port ducting, and a resonant chamber. KIPS is operated by a mechanical governor.

看不懂.....您能解釋一下嘛?

看不懂.....您能解釋一下嘛?